Captain (Res.) I. Fogelson

Captain(Res.) M. Keisary

Editor:Commander (Res.)R. D. Koehler.

Captain (Res.) I. Fogelson

Captain(Res.) M. Keisary

Editor:Commander (Res.)R. D. Koehler.

Genesis,

Genesis,The

unexpected assistance

On January 15th 1991, the Gulf War broke out and the next day Israel experienced

for the first time the long distance ballistic missiles attack on its civilian

population, the main threat was from the possibility of chemical warheads that

were developed with the support of German companies.

As a result, after the end of the Gulf War, the German Government offered humanity

and military support, An Israeli delegation was sent to Germany and late at

night on January 30th Chancellor Kohl approved an assistance package including

the construction of two Dolphin submarines. The project was again on its way

and the contract was rewritten and signed on April '91.

It was not before '93 when, with the strong support of the late PM Yizhak Rabin,

the Israeli Navy Commander in Chief, RADM Ayalon stated its policy and priority

in such manner that could result in terms of contract amendment on April '94

which actually added the third boat to the scope of work.

The first of class was launched and named in Emden on April 15th 1996 and the

third on July 9th 1998.

All along the project a Navy staff comprised of experienced submariners and

engineers were posted as inspection team in all major locations of activities.

As early as Sub-Con '95, very well organized by the German industry in Kiel,

we could sense that the "Dolphin" is about to be a leading submarine, representing

a state of the art technology and fulfill highly crossbar of operational demands

and requirements.

The

Operational Concept

Israel has a long coast along the

eastern edge of the Mediterranean considered to be a strategic asset, the only

open free gate to the western world. No nation would voluntarily give up such

an asset of an open sea with its two facets, the surface as well as the under-water

domain. Obviously it should be on the Israeli agenda as well, not forgetting

that the 56' and 67' Wars were started as a result of the Red Sea blockade.

Israel has a long coast along the

eastern edge of the Mediterranean considered to be a strategic asset, the only

open free gate to the western world. No nation would voluntarily give up such

an asset of an open sea with its two facets, the surface as well as the under-water

domain. Obviously it should be on the Israeli agenda as well, not forgetting

that the 56' and 67' Wars were started as a result of the Red Sea blockade.

In the mid 80's the existing submarines in service were about to commence the

mid-life conversion and in combat we were about to face already exist as well

as future threats, like the ASW Helicopters and long range ASW capabilities.

This situation dictated up grading of the submarine force, which led to a new

type of boat. The main tasks of the submarine are:

|

Taking

into account the arena and the threats we facing, it was necessary to extend

the submarine capability to stay submerged and still keep maximum combat readiness.

The transit average Speed of Advance (SOA) normally would limit the boat and

might cause a situation of "missing the action". Therefore the submarine has

to be able to reach long distance destinations at a shortest possible time in

a maximum discrete manner.

Extending the submarine capability to stay in the enemy waters would save unproductive

transits as well as increasing the operational flexibility in combat scenarios.

Hence we ought to increase the engagement capabilities by having more torpedoes

and missiles to a greater range. The availability of the weapon is, among other

factors, a function of number of tubes, variety of armament and capability of

quick reliable reload.

Aiming a design goal of greater survivability in an environment of modern ASW

platforms and Helicopters it is bound to reduce drastically the "indiscretion

rate" which means less time snorting for more SOA in a lower level of self-noise.

Using modern long-range weapons dictates also long range detection and classification

capabilities to maximize the advantages derived from the armament in use. It

means, among other features, long range low-frequency sonar and great effort

to keep low level of self-noise at all modes of operation.

Increasing the efficiency of the crew can be obtained by setting higher degree

of reliable automation as well as considerable improvement in their living conditions.

The modular design of major systems would enable future growth in accordance

to new operational requirements, which expected to arise along the submarine

service.

As all the above mentioned considerations might lead to a much larger displacement, yet there are some arena features that force the designer to give a great deal of attention and priority to high maneuverability in constrained shallow water which means limited submarine displacement. Let alone this constrain would also serve the requirement for high degree of survivability as well as low target strength to stay undetected. Having said all that we can summarize the operational requirements and the design goals of the submarine as follow:

The

combat system:

The combat system should be considered as the heart of the "stealth machine"

while all other platform systems have to serve the purpose of positioning the

boat "on time, on position, on target" meaning, in the right place, at the right

time and at the adequate depth. By that it will be possible to extract the submarine

advantage upon its opponent and achieve the ultimate superiority.

The more integrated and sophisticated the combat system is, more likely it would

support decision-making process of the commanding officer and the attack team.

Moreover, integrated system accelerate the process of detection and classification

thus give an early warning of possible threats which helps to avoid being detected,and

be able to fulfill its task.

Hence, despite all technology sophistication the end result very much depends

on the command-team capabilities to monitor, control and "criticize" the computer

recommendations. This process would ensure the weapon would pursue the real

targets and not virtual ones.

Unlike combat systems of old generations, where it was comprised of group of

"stand-alone" systems with limited number of functions, the "Dolphin" combat

system is an integrated one, enabling all the subsystem work together to create

an optimum tactical picture by using Multi-function Consoles (MFC).

The modern surface vessels and submarines, the long range of detection and weapon

capabilities set a significant challenge to the submarine's combat system which

is expected to detect, analyze, classify and recommend solutions and assign

the weapon as fast and accurate as possible. This means implementation of high

level of automation and technology.

A major part of the "Dolphin" combat system was developed by STN-ATLAS as few

steps forward from successful sonar and combat systems like ISUS 83. It is a

new generation, ISUS '90 "tailored" to the specific requirements of the IN to

manage, handle and control its own sonar as well as all other Government of

Israel Furnished Equipment (GOIFE) such as Periscopes, ESM, Communication, Navigation

etc. The technology in use and the integration of the combat systems enabled

to minimize the time needed between detection and actual engagement.

The system consist of:

In order to intensify the system efficiency it handles and controls also "external" systems like

The Weapon Control

The integrated STN-ATLAS combat system has all vital information on the tubes

and weapons. As soon as a target is selected, the adequate weapon is assigned

and automatically the relevant firing data is injected as a pre-setting to the

selected weapon. In case torpedo was fired against surface or submerged target,

a guidance procedure can be initiated, either automatically from the combat

system or manually by the operator.

Weapon handling is managed via the Torpedo Control System (TCS) in the forward

compartment (loading, reloading, flooding the torpedo-tubes etc..)

Platform

technical description and philosophy

Platform

technical description and philosophy

The safety concept, based on the traditional German design, is primarily based

on the high strength of the pressure hull. In case of malfunction or accident,

it is assumed that the pressure hull will remain intact and the submarine can

be brought to the surface quickly by blowing out the ballast tanks using Emergency

Blowing System.

To support this concept, each opening in the hull is double sealed from the

sea (i.e. Hull valve and Secondary Hull valve). The valves are monitored and

controlled from the Engineering and Monitoring Control System (EMCS). From this

station the crew can also control and monitor all the technical system with

maximum efficiency and safety.

The need for increasing maneuverability is relevant for operations in coastal

and shallow waters, and is met by the high performance X-rudders configuration

and the position of the forward hydroplanes on the forward casing, operated

from the Steering Station (STSN) by one helmsman.

One of the major factors in the modern Anti Submarine Warfare, is the Signature

of the submarine, therefore Signature Management was one of the major efforts

in the design and the construction of "Dolphin" class submarine.

The ability to achieve long missions is also related to the reliability of the

technical system with high level of redundancy. The main three rules in the

system design were:

Main Characteristics

Dimensions

The

Hull

"Dolphin" class Submarine hull configuration is the traditionally "Single Hull"

Submarine. The line design is optimized to get low resistance and to avoid flow

Noise. Closing all the openings that are not in use permanently also eliminates

flow noise, achieving the effect of "Closed Hull".

The pressure hull of "Dolphin" is made out of the well known and proven steel

for submarine with high strength and elasticity - HY 80. The strength of the

pressure hull is calculated with safety factor of 2. The design and the construction

were proven by diving test to depth greater by 25% of the Maximum Operating

Depth, and Strain measurement in more than 100 location along the hull.

The pressure hull has been optimized to the maximum useable space inside the

pressure hull for a limited maximum displacement. This constrain was given during

the design, in order to meet the requirement for a "Coastal Submarine".

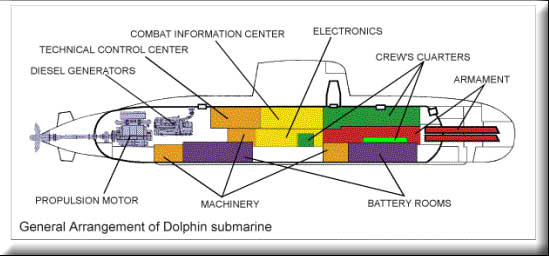

The general arrangement (from fwd to aft): The unique design allows a

two-deck arrangement along most area of the boat.

|

General arrangement

|

|

| Engine

Room (ER) located in the aft part, has one deck, main components located in the ER:

|

Hydrodynamics

and maneuverability

With Optimum line design and with relative low length to diameter ratio, "Dolphin"

Submarine has very high maneuverability. It is steered by high performance x-rudders

configuration and forward hydroplanes located on the forward casing.

From practical reasons of mooring alongside the peer, the size of the x- rudders

was limited to the hull diameter, therefore two stabilizers has to be added

in order to get positive dynamic stability in all speeds.

Maneuvering and controlling the boat is done from the steering station (STSN),

which is a double seat, "One Man Control" Stick wheel configuration, design

by "Ferranti" and later taken over by GEC Marconi.

The STSN is fully redundant system, the major features are:

The Man-Machine

Interface (MMI)

As a result of special attention to the MMI, the operator control and operates

the boat with the four display screens, Dedicated Control & Monitoring Panels

(DCMP) and Hard Wire Control Panels (HWCP) which are mainly for safety units

(e.g. Secondary Hull Valves). Depend on the frequency of operation, each unit

or complete process may operate from few locations (e.g. keyboard and screens,

DCMP and HWCP).

Ship's Technical

System

Propulsion system

The propulsion system is a conventional one. Consist of two of Batteries sets

supply the power to the main switchboard. The main switchboard connects the

Batteries and the Main Propulsion Motor in a way that it's possible to supply

the necessary power needed by the propeller.

The Main Propulsion Motor is directly connected to the propeller through a flexible

coupling, by the Propeller Shaft.

Torpedo Tubes

The 10 Multi Purpose tubes are installed forward, penetrating the forward dome.

These tubes are design to 21-inch diameter weapons. The weapons may be Swim-Out

or ejected by hydraulic piston. Quick reloading is possible with the Embarkation

and Storage System, which is installed behind the tubes. The spare weapons are

ready to load since they are seating just behind each tube set.

Most of the functions of loading and firing the weapons into the tubes is done

from the Tube Control System (TCS) and the Embarkation system. Some of the functions

are done in "close loop" process (e.g. tube flooding or draining, set to ready,

fire sequence)

Hoistable Masts

In order to allow high speed in periscope depth, all masts are streamline faired.

The fairing avoid direct sea load on the mast, therefore vibration are reduced

to minimum. The fairing is also reduced the wave making which is one of the

main parameters for RCS and optical recognition.

To minimize the waste of internal space, most of the masts are "non-penetrating

masts" i.e. telescopic extension in the bridge fin. The penetrating ones are

the periscopes, since their optical line of sight, and main communication mast

since it is a long wipe antenna. The new snorkel concept, allow "preparing to

snorting" under water.

Accommodations

In order to keep the crew in shape for long stays at sea, the Accommodations

were design to allow them to rest, to dine or to have entertainment in parallel.

i.e. banks rooms are dedicated for sleeping, and in addition there are messes

for eating etc. Increased number of toilets was installed in order to improve

crew comfort.

Large space of refrigerator room allows keeping fresh food for long time.

Emergency

Deballasting System

With the experience of the Hydrazine Emergency System which is installed on

the existing submarine, "Gal" Class, and with consideration of the advantage

and disadvantage of that system, the IN has decided to develop new Emergency

Deballasting System which is working on High Pressure (HP) air installed onboard.

The principle is very simple: supply large amount of air into the Forward Main

Ballast Tanks in the shortest time possible.

The emergency blowing system consists of: approx. 9 m3 of HP air in 250 bar,

large diameter piping system (DN80) and special developed control valve, that

controlled the overpressure in the main ballast tanks. The advantages of this

system are:

Safety envelopes

The Safety Envelope (SE) defines the domain that the submarine must stay in,

to guarantee that in case of an emergency situation, special recovery maneuvers

will avoid the loss of the submarine. The two cases are major malfunction in

the control surfaces (planes) and water inrush.

Using the performance of the Emergency Deballasting System, the SE was derived

from the results of a large number of maneuvering simulations, which were done

on different sets of initial conditions.

The results were represented by set of empirical equations, which are basically

continue limiting the control surfaces deflection angles, depends on the boat

conditions (speed, trim, depth, and distance from surface or seabed).

In case of water inrush, the use of Emergency Deballasting depends mainly on

depth and the ability to tight the boat. The SE is integrated in the STSN. Therefore

the rudders' operator gets information about the free space for maneuver, or

alarms, in case the boat penetrate the SE. In automatic mode (Auto Pilot engaged)

the control surfaces are actually limited to a specific deflection calculated

by the SE.

Rescue and

Escape

Whenever the recovery actions are failed, the crew may rescue itself from the

sunken submarine with the aid of Rescue Jerking suit and the supported system-

Built In Breathing System (BIBS). If the Boat lay down on the seabed and still

intact, the crew may wait to rescue by the DSRV, or to escape from the access

trunk with the Hood Inflation System (HIS).

To support the rescued crew there is one raft including distress transmitter,

packet into a sphere. When the sphere released from the submarine and get to

the surface, it is open and the raft afloat and the distress transmitter starts

to transmit an SOS signal. In addition it is possible to send signals to the

surface via the Submerge Signal Ejector (SSE).

Conclusion

Although the complex "Dolphin" project has not yet finalized it can be said

at this stage that the IN will soon be equipped with first-class submarines,

which are in many respects the state of the art. In a submarine of its size

the Contractors and the IN achieved maximization of capabilities, integrated

combat systems and automation in such a level that would permit to keep the

complement as small as possible even in comparison to smaller submarines. It

goes without saying that the result of such a project could not be achieved

without the full cooperation and support of all parties involved. Shipyards,

IKL and STN-Atlas had to exercise their utmost talent and capacity to meet the

demanding challenge of the contract.

Last updated by: Ronen at 11.12.99

Copyright © 2000 - All Rights Reserved